1. Introduction

It is widely recognised that the circular economy (CE) is gaining ground through a pyramidal increase [

1,

2,

3]. Not only is academia contributing to this widespread diffusion but policymakers and public bodies (such as the European Commission) are also boosting measures, grants and research agendas to pave the way to achieve the so-desired transition to a complete CE. This paradigmatic shift certainly affects several industrial sectors, envisioning that a CE will reduce pressure on natural resources [

4].

Both public and private efforts devoted to promoting CE across countries and sectors have been driven to improve resource efficiency, minimise external material supply dependence, and reduce waste in many sectors [

5]. Resource recovery models offer the industry new challenging business opportunities such as obtaining new secondary raw materials (SRM) from end-of-life products and sub-products that, through (pre-)processing, can be used as an input for industrial production, for example, the industrial and household landfilled wastes. Within resource recovery, reusing ‘waste’ as a new secondary raw material is gaining attraction as it allows shifting economic benefits into social and environmental benefits by preserving the technical value gained from products [

6].

Undeniably, pulp and paper (P&P) producers have been at the forefront of the transition towards a circular economy in Europe, and significant strides have been made to valorise the waste produced by this industry [

7]. Currently, environmental aspects are becoming major issues that need intervention in this sector due to the large amount of solid waste generated by P&P mills. Around 400 million tons of paper and paperboard are produced globally, and estimates suggest that global paper consumption in 2025 will amount to 500 million tons [

8,

9]. In addition, according to the Confederation of European Paper Industries (CEPI), Europe is the world’s second-largest producer of pulp and paper, with 35.2 Mt/y of pulp production and 52.6 Mt/y of paper recycling [

10], producing nearly 88 Mt ton of paper articles (2022), which represents almost about a quarter of the world’s production (The Confederation of European Paper Industries, 2021). In Europe, 11 Mt of solid waste, including 7.7 Mt of waste from recycled fibre processing, was generated during the production of 99.3 Mt of paper [

11,

12]. This means a generation rate of approximately 11% of solid waste vs. paper product, landfilling being their major option, except in some valorisation cases, such as the use of deinking sludge from recycling paper mills for energy obtention and the generation of inorganic materials. Inorganic solid wastes (e.g., green liquor dregs (GLD), slaker grits (SG), lime mud (LM) and boiler fly ash (BFA)) require an environmentally friendly solution [

13] as long as they are produced in high quantities and landfilling is still the main disposal method; hence, techniques to valorise these wastes are seemingly important [

7]. In fact, around 70–75% of solid waste from paper mills has been disposed of in a landfill. Paper solid wastes vary greatly in type and amount, according to the process type [

14,

15]. In Europe alone, pulp production generates the following solid wastes: boiler ash (32% of the total solid waste, 2.08 Mt/y—estimation), fibre sludge (16%, 0.93 Mt/y), slaker grits (6%, 0.35 Mt/y), lime mud (29%, 1.68 Mt/y), and GLDs (13%, 0.75 Mt/y). The paper recycling process, on the other hand, produces the following solid wastes: wastepaper ash (32%, 1.24 Mt/y), clarification sludge (5%, 0.19 Mt/y), deinking paper sludge (47%, 1.82 Mt/y), and paper rejects (16%, 0.62 Mt/y).

As one of the key contributors to the European economy, global trends are moving the P&P industry (PPI) into a new landscape, for example, giving way to more collaborative structures with players in and outside the industry [

16]. Since Europe is today facing the challenge of resource scarcity and efficiency, PPI waste can become a valuable secondary raw material (SRM) for other resource-intensive industries such as construction, which accounts for 50% of the world’s energy use and 40% of raw material consumption if managed sustainably (COP26, 2021). In such a context, CE represents a promising strategy for reducing PPI’s negative environmental impacts while discovering new competitive advantages through novel business models [

17]. New widespread markets are needed to extend the valorisation operations, reduce landfilling rates and increase the competitiveness of the PPIs to create new added-value markets for their inorganic waste. New opportunities via strategic sector partnerships and low-carbon and sustainability-driven innovations can help PPI to move forward to new market opportunities through circular strategies [

18,

19], and building business models based on integrated value chains that meet changing societal needs is becoming essential [

19].

Considering the potential advantages of providing valorised wastes from PPI to sectors with intensive raw material consumption, such as the construction sector, it is evident that it holds great relevance. Expected returns from PPI investments in sustainability, as recognised by Toppinen et al. (2017), have also been highlighted by experts who posited that as much as 40% of the industry turnover could come from new circular products in 2030; however, they were concerned about the inability of the sector to realise this potential [

20].

In the context of this paper, the circular economy emerges as the strategical framework that provides managers with principles, strategies and means for implementation within their organisations. This becomes especially relevant when transitioning from existing open production systems based on a linear consumption model to ensure the sustainability of the entire business network. Having explored different patterns of circular models [

21,

22,

23,

24,

25], we focused on identifying the key elements for designing new business models under a circular economy perspective and within the category of resource recovery scenario [

6]. Aiming to contribute to CE literature and, more importantly, to provide managers with a tailored framework that facilitates the transition towards more circular products and services design, this research placed its focus on the design and operationalisation of circular business models. This research contemplates CBM as a new kind of BMs, where the value creation, delivery and capture are grounded on demand and supply sides. More concretely, the circular business model design and its operationalisation aim to promote new economic value embedded into new types of market offerings minimising waste in the PPI industry as well as promoting sustainability and customer satisfaction through circular products with a lower environmental impact in the construction sector.

The present article deals with the development of methodological guidance for circular business model (CBM) development and implementation, focused on a clear target orientation and definition of the ways to goal attainment by analysing the results of the pilot scale experiences gained from three case studies in the construction sector, conducted by the authors within the framework of the ‘paperChain’ EU-funded project. This methodology allows for the examination of both technical and non-technical factors that may impact the potential development of CBM and how they can be managed for achieving a successful circular business model under a resource recovery strategy and, more concretely, with the PPI sector as a provider of secondary raw materials to the construction sector.

Building upon the above analysis, this paper is structured as follows:

Section 2 provides a literature review that explores CBM development through resource recovery strategies and the extant frameworks for developing them resulting in identified gaps from an operationalisation perspective. The framework to create and design resulting in an implementation methodological guideline is explained in

Section 3.

Section 4 presents three cases and how they contribute to validating and refining the key elements of the framework. Based on these cases, the methodological guideline for the design, launching and implementation of CBM was refined.

Section 5 and 6 draws discussion on the research results final reflections on the conceptual framework and conclusions and final reflections on the conceptual framework.

2. Literature Review

It is remarkable how the wide range of theoretical influences on the circular economy, as highlighted by Homrich et al., originates from diverse fields, including economics, biology, environment, and strategic management [

1]. The growing body of literature on sustainable and circular business models has fostered the propagation of many review articles trying to address the lack of clarity surrounding the concepts of CBM, organising concepts, archetypes, case studies, etc. [

1,

2,

3,

26,

27]. This section aims to present relevant theoretical evidence that informs our analysis of the creation and operationalisation of CBMs within the context of business innovation through resource recovery models. The objective of the literature review in this paper is twofold: first, to understand the factors that have an impact on circular business model development and, second, to identify extant frameworks for developing CBMs and their strengths and weaknesses for the context of this research.

2.1. Circular Business Model Literature within Resource Recovery Strategies

Despite the importance of the CBM concept, there is already a considerable lack of clarity and real understanding of its theoretical conceptualisation and position in economic literature [

3]. More examples for comparison between value proposition, value capture, value delivery and value creation would clarify real practices of CBM [

2]. Building upon the theoretical research study regarding circular economy and circular business models, this work revisits several relevant concepts from the literature to refine that initial development [

28] to move forward with the implementation of CBM. The wide range of literature focused on circular economy and its archetypes did not allow us to identify the main drivers for implementing the circular economy within organisations. In that sense, and taking into account that business model innovation enables a systemic transformation in the fundamental principles of businesses and aligns the incentives of various stakeholder groups [

29,

30], circular business model innovation was explored by this research as one relevant driver for implementing the circular economy within organisations. The intention of the review presented here is to explore key sources that span from the concept of circular business model innovation (CBMI) to literature about business cases for sustainability. This allowed authors to identify those research gaps that should be covered to create and operationalise CBMs.

Table 1 summaries the main findings obtained from the literature review.

Based on the analysis shown in

Table 1, several enablers of CBM implementation were identified as relevant to the aim of this research. Depending on the literature update, we found that focusing on business models is not enough, and the transition towards circularity supposes deep modifications. Firstly, focusing on the design of a good/service is not enough; approaches such as eco-design or green design offer limited results [

36]. Instead, there is a need for a systemic approach centred not only on one company but also on a consortium that collaborates (ecosystem) [

31,

32] and guarantees the interactions among all stakeholders involved in innovating the CBM. Hence, the organisational and the system strategic levels need to be defined in advance in which all stakeholders involved in the CBM must be represented: the firm, the partner network, the environment, the decision maker, and the customer [

27,

28]. Such an ecosystem perspective entails guaranteeing trusted collaboration, solid communication and coordination within complex networks of interdependent but independent actors/stakeholders [

29]. Aligning the value proposition to customers’ needs to the cost and revenue streams, as a second challenge, implies reinforcing several adoption factors that can hamper the implementation of innovative CBM [

22]. Those adoption factors range from technological to non-technological elements of the CBM such as governmental structures providing long-term and consistent support frameworks, enabling circular economy activities; legal and regulatory support (e.g., product and material eco-design); availability of investment capital (e.g., for new infrastructure) [

40]; socio-cultural specifications and physical and social proximity between the stakeholders [

39]; proactive strategic management, which results in the regular creation of business cases for sustainability; attractiveness as an employer (indirect influence); and innovative capabilities that have an indirect influence [

37].

The challenge of fostering a deeper comprehension of how to innovate within circular business models has led to the identification of several critical factors that, incorporated in any reference framework, will ensure success in their execution: top-management commitment from each of the firms participating in the system; creation of a well-defined partner network in favour of organisational innovation and market share growth; monitoring of the influence of value creation capacity over such a partner network; the performance of the circular business model should be measured through the selection of the appropriate KPIs that will be specific for each context; and the relationships between capabilities, processes, culture and strategy, on the one hand, and several mechanisms for their adaptation and integration in the global system, on the other.

2.2. Extant Frameworks for Developing CBMs

Despite the growing popularity and momentum of the circular economy (CE) concept, numerous scholars have consistently emphasised a shared research gap, namely, the need for further development of the knowledge and tools required to effectively implement it in practice [

6,

41,

42,

43]. Thus, the second literature evaluation focused on exploring existing frameworks for a CBM practical implementation that better fits with this research’s objectives.

Within the growing body of CBM articles (see

Table 2), there is a recognised need for tailored frameworks that facilitate the transition to a circular economy through circular business model design. These frameworks aim to deliver environmental and social value while also ensuring economic benefits [

21,

35,

44]. This requires not only the creation of value for a network of stakeholders (including society and the environment) but also for the firm [

38,

45].

Some influential studies as examples of frameworks providing managers with guidance for CBM creation and implementations include, among others, the value mapping tool for guiding firms in creating value propositions better suited for sustainability [

45], the framework created by Antikainen and Valkokari for sustainable circular business model innovation [

35] or the decision support tool for managing circular buildings and related supply chain collaborations [

43]. These frameworks have envisioned relevant improvement areas to CBM design. In this regard, the value mapping tool developed by Bocken et al. (2013) aimed to support firms in gaining a deeper understanding of sustainable value creation within their business activities. It focuses on achieving a better balance in value creation for all stakeholders, including society, ensuring that conflicting demands are addressed and negative outcomes are minimised. Bocken et al. point out that such a balance effectively provides valuable support for organisations in their pursuit of sustainability, although its implementation requires some experts’ facilitation to obtain the best results (sustainability innovation demands looking outside existing business practices). Therefore, they recommended the development of a complete toolset to assist organisations in developing complete solutions within the CBM context. Built upon Bocken et al.’s tool, Ferlito and Faraci (2022) develop a new structured framework combining elements and characteristics of various tools of both academic and practical matrices [

46]. While the innovative framework of Antikainen and Valkokari (2016) introduces the role and relevance of systemic innovations, further longitudinal studies could enhance the understanding of the crucial stages involved in the processes of business model innovation through intentional design or re-configuration [

35]. Although focused on the building sector, Leising et al. (2018) conceptualise the organisational aspects of circular value chain collaboration by connecting and integrating the fields of sustainable supply chain management and the CE [

43]. The authors recommend further improvement of their conceptual framework, suggesting deepening the relationships between its four building blocks (vision, actor learning, network dynamics and business model innovation) since their proposal was mainly descriptive. Providing further elaboration on each building block can be reinforced by exploring patterns, mechanisms and levels of performance [

43]. In addition to the room for improvement previously identified, Hofmann (2019) stated that in transitioning from linear to circular business infrastructures, firms need to establish new collaborative production and consumption networks that facilitate the implementation of circular value creation and offerings [

47]. As a result, the business models of participating manufacturers, service providers, retailers, logisticians, and other stakeholders must align, interconnect, and harmonise with each other. The concise description provided by Hofmann (2019) enables a systematic analysis and assessment of the normative and operational aspects of the theoretical foundations of CBMs. It covers the desirability of CBM implementation (normative dimension), the definition of potential approaches and offerings (strategic dimension), and the practical and feasible solutions that can be implemented at present (operational dimension) [

47] that constitute insightful aspects to be integrated within a more comprehensive framework.

The literature review and the aforementioned frameworks reveal significant opportunities for improvement that must be tackled to ensure the successful practical application of CBMs through the creation of a more comprehensive framework. Overall, this research study has focused on four elements identified by their authors as promising areas to advance the transition to a circular economy. Firstly, the role of technological and non-technological aspects within the system deployed by the CBM must be identified such as top-management commitment; a well-defined and trusted partner network in favour of organisational innovation and market share growth; monitoring of the influence of the ecosystem’s value creation capacity; a sound performance monitoring scheme that will be specific for each context; and the relationships between capabilities, processes, culture and strategy. Secondly, while some existing frameworks focus on a holistic perspective when defining the value proposition of the CBM, considering the collaboration between all value chain agents, it would be desirable to incorporate the perspective of the ecosystem and its value proposition. The third element relates to incorporating the three dimensions of sustainability, that is, all activities and processes that guarantee not only economic but also social and environmental impacts on the CBM’s whole lifecycle. Finally, the most noteworthy factors influencing the development of CBM in any kind of CE scenario may entail addressing different stages of its life cycle to guarantee expected success.

3. Research Method

A precedent theoretical reference model consisting of an interlinked set of building blocks that stands for a structure supporting firms (or systems) in producing innovative and value-added solutions under a collaborative perspective [

28] is taken as a basis for creating and implementing circular business models on waste valorisation-based products.

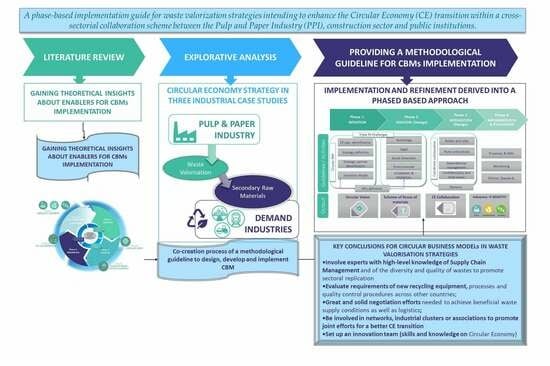

Its elements are appropriate to provide orientation, guidance, support, and a basis for communication guiding companies in planning, operating, and controlling corresponding circular business models. Moreover, it requires moving forward to analyse and explore the real application of an implementation scheme, with specific steps showing how the identified areas for improvement would enhance the CBM implementation. In that regard, a methodological framework was outlined (see

Figure 1) to study the value ecosystem and collaboration for CE guided through four stages with their main outcomes. This research study describes a phase-based approach in the form of a practical methodological guideline, supported by different elements, activities and proposed tools to create the innovation ecosystem formed by companies involved in the development of a circular product with a sound roadmap to follow.

Every phase has a well-defined objective supporting the creation and effective operation of a CBM, as explained below:

The initiation phase aims to establish the CBM strategy and its associated elements, such as circular economy opportunity identification, strategic motivation and strategic partner identification, leadership and co-leadership. It starts when one or more organisations (hereafter ‘CBM leadership’) identify the need or opportunity for the creation of a CBM and take the lead for the creation of the ‘CBM ecosystem’, being the main party responsible for the definition of the CBM model’s strategy, as well as the involvement of relevant partners; eventually, an initial scheme for transition model can be envisioned that encompasses the expected performance by all its members. When the ‘CBM leadership’ identifies an opportunity to create value-added solutions under a collaborative perspective, it shall assess the possibility of tackling this challenge in a long-term collaborative way by analysing two aspects: (1) the motivational factors of the creation of a circular economy model and (2) the factors and forces embedded in organisations (e.g., culture, experiences, knowledge, operating routines, etc.) that might represent higher or lower aptitude to accept new production or organisational solutions for such a collaborative innovation process that CBM embodies. Finally, the strategic goals are defined as well as further selection of strategic partners.

The ideation (design process) phase aims to define how the CBM creates, delivers and captures value, from business, technical, social, legal and environmental perspectives, and how economic and financial viability can be depicted. We have integrated into this phase six building blocks that group all critical elements as the set of enablers, success factors and barriers of a circular economy model of resource recovery. Under this ideation phase, circular business model innovation is defined as an iterative process that helps to define the CBM global vision and is updated along the three first stages.

The integration phase is related to the definition of the CBM’s decision-making model, including governance rules or policies, bodies and roles. The third phase of the creation of a circular economy model is related to the intensive collaboration of the companies involved in the CBM throughout the system. In this stage, the CE leadership will lead the collaboration of the members of the ‘CE ecosystem’, being the main party responsible for guaranteeing information exchange and agreements about responsibilities, liabilities, sharing profits, goals, knowledge and ownership. Therefore, the key challenges in this phase are rooted in defining the governance model of the ‘CE ecosystem’. This will guarantee that both the economic and technical dimensions of the CBM are rooted in the collective strategic objectives.

The implementation phase covers the operational structure of the constituting elements of a CBM, namely, the processes, skills or capabilities, and activities as well as their alignments with the CE ecosystem’s strategy and culture perspective. This phase shall address the operational structure of the constituting elements of a circular economy model, namely, the processes, activities, and skills that will constitute the organisational readiness of the members of the CE ecosystem.

A complete guide to each phase was created considering the key elements (see

Supplementary Material), as graphically shown in

Figure 2. It was deployed to assist companies in defining their strategic vision of a CE transition model, designing a business ecosystem based on the main pillars of sustainability, considering technological, legal, economic, environmental and social factors and, lastly, measuring the effectiveness of the CBM implemented.

To test the methodological framework, it was applied in real scenarios and, inspired by similar approaches (Yin, 2014), followed an inductive approach. Given the innovative nature of the project and the lack of a regulatory framework for waste recovery added to the reluctance of many construction sectors to work with waste (and in some cases, with little experience or limited knowledge), there were no clear premises to apply deductive reasoning. Instead, the inductive reasoning was applied based on a set of specific observations about three exploratory case studies, which have served to identify relevant factors for the effective implementation of CBM and thus helped to overcome the improvement areas identified in the literature review. Three case studies resembled novel waste valorisation strategies for PPI-produced secondary raw materials (SRM) to obtain innovative low-carbon footprint construction product designs. Within this context, the selection process had to ensure solid knowledge and experience, as well as the responsibility of the representatives of all companies to be interviewed within the decision-making processes; therefore, they were meticulously selected by the stakeholders of the CBM considering their roles within their companies, that is, the waste supplier, the waste manager, the construction company, the R&D technology centre and the logistics company.

Regarding the tools used for data collection, two approaches were followed, which were complementary: semi-structured interviews supported by a survey covering all the elements of the methodological framework according to the stages (see

Supplementary Material) distributed online and one-day creative workshops were arranged in each city with several participants of the companies of the ecosystem. The interview procedure was supervised following the ethical recommendations from the European Commission. An informed consent form was initially shared with participants so that they were informed about the type of data required throughout the process and aware that no personal data were required from them. The data-gathering process ran from June 2017 to June 2018 with these companies and focused on strategy, objectives, operational context and indicators concerning the circular business model from a qualitative perspective.

After collecting and processing the primary data through the tailored semi-structured survey, a one-day creative workshop was arranged in each city conducted with the components of the CBM ecosystem (see the Acknowledgements). As for the creative workshops, the aim was to invite and concentrate the same participants in the interviews. Each interviewee was previously informed about the issues that would be discussed during the workshop so that they were duly informed about the regulatory standards related to the ethical issues of the process. They receive detailed information about the contents of the interviews avoiding gathering any personal data. Aiming at data triangulation purposes, those workshops involved several informants with different roles in the ecosystem in order to validate interpretations of all the stages, their components and those interactions between members of the ecosystem. The evidence-based data received through the semi-structured survey was tested. Those workshops allow contrasting what different interviewees from the same CBM explained on their complex organisational routines, processes and decisions as well as obtaining data about how they perceived their visions of the CBM in their firms and address collaborative decision-making. Data were collected until comprehensive analytical insights and conclusions were derived in an improved and tailored methodological guideline.

4. Results

4.1. CBM 1: Innovative Circular Business Model for Green Concrete and Asphalt Manufacturing

This CBM valorises PPI causticising lime ash, dregs and grits, obtained in pulp production based on Eucalyptus globulus wood source material, as SRM at a demo scale in Portugal for two demo cases: (a) green concrete for building, in which natural calcareous filler added to the concrete was replaced by lime ash (LA), added as a mineral addition in pre-cast concrete elaboration; (b) asphalt pavement manufacturing, in which part of the asphalt mixture aggregates was replaced by PPI wastes, green liquor dregs (GLD) and slaker grits (SG).

Following the reference framework (

Figure 1), in the initiation phase, pursuing identifying the value proposition of the CBM, the CBM’s leader set up and encouraged several actors to deal with the best alternative waste management and processing with the help of the waste generator (PPI), the R&D manager of the PPI, a local waste manager, and two end-users of the greener product (concrete manufacturer for buildings and road asphalt deliverer). Although there were no previous R&D projects amongst the companies involved, the CBM was built on existing closely located innovation structures. It is worth noting that PPI is a very important sector in Portugal, so the participation of a large/leading manufacturing company and the proximity of stakeholders accelerated the initiation process. A tight communication plan was developed among partners with clear strategic objectives since the CBM ecosystem dynamic is crucial in this phase, clarifying participants’ roles and development steps. Looking at the strategic, market and organisational objectives highlighted by the companies involved, this CBM 1 stands out mainly for its positive effects on the sales products of the companies involved; all companies are interested in creating/increasing their reputation in the field of circular economy and valuation of materials within a closed-looped system. More concretely, the PPI envisioned future restrictions and increasing costs associated with landfilling such wastes. Key stakeholders are included based on criteria such as their significance, replaceability, cost level, and performance. In this case study, the CBM leader played a connecting role as a technology developer, bringing together supply chain actors, while the waste manager played a vital role in the CBM, overseeing pre-treatments and transports and foreseeing the technical–economic issues of scaling up the approach, together with SME constructors.

Throughout the ideation phase, the scheme for material reuse was outlined, scrutinising technological, legal, economic, financial, social and environmental conditions. A collaborative attitude among the CBM actors facilitated further key information exchange in terms of targets, requirements, material qualities, treatment processes, product eco-design, exploitation, environmental footprint, logistics and skills. Regarding the technologies and processes, novel waste management procedures involving drying, milling and transportation fit with the CBM investment planning for resource recovery, where the local supply becomes decisive in achieving targets on reducing transport costs and carbon footprint. No new or ad hoc designed equipment, qualifications or skills were needed for waste handling operators since the waste quality variation was low, not being a bottleneck. By the time this paper was written, no subsidies or monetary compensation were granted in Portugal to companies that valorised this type of waste. All the participants agreed that, in addition to the administrative excessive burden release, “the creation of a ‘green’/sustainable label associated with the final product could help the image of the product in the market and consequently help in opening new markets” and that “economic incentives to facilitate CE transitions should be provided”. Environmental risks derived from the use of these wastes were considered not highly relevant since they are incorporated into encapsulated products. However, the regulatory framework on PPI waste valorisation in construction is not yet updated in Portugal, where obtaining the “waste end-of-life” (EOL) status, necessary to achieve the “secondary raw-material (SRM)” designation and, hence, to serve as a construction material, constitute a serious barrier in the long term. In this regard, the applicable too-conservative policy and regulatory environment again implied a challenging deal for the members due to the lack of approaches supporting the CE, starting at a national level and for which an increased effort to unify laws in all EU nations, and in the specific case of Portugal, an ‘innovation deal’, was demanded.

The integration phase focused on establishing the ‘collaboration scheme’ of the CBM was supported by previous relationships between the ecosystem members in Portugal. In this case study, the network dynamic was assured through the intermediating role of the CBM leader, who was responsible for the CBM entailing management (memberships, cooperation and confidentiality agreements) and monitoring CBM performance (KPI selection). From a cultural perspective, there was trust during the negotiation meetings between members. As PPI stated, “the base of the relations between the partners in the CBM is trust, so the confidentiality of the transmitted information among partners is assumed and respected”; this is why companies had bilateral negotiations involving the waste manager playing the role of ‘external partner’ to assist in the demo cases. The last element to consider at this phase relates to resistance (internal or external). The sound cooperation and alignment of the stakeholders of the whole value chain were assured and resistance to the ‘linear’ system did not appear relevant enough to set up any measure to boost the transition at the early stages. However, as the CBM evolved, the cooperation and alignment suffered since the transaction costs produced certain tensions that the CBM leader was responsible for managing, providing a complete transition model for the new circular by-product with mutual adjustments of product parts, service elements, and production processes across company borders.

Finally, the implementation phase reflects on the specificities of the two demos in CBM 1 since they have similarities, but relevant differences must be noted. The demo case ‘Lime ash Concrete Pre-casts’ implied the use of PPI lime ash, basically limited by its classification as “waste” and the lack of a specific legal framework for lime ash use in concrete production. Pre-cast pilot production was carried out covered by common standards employed for the construction of the structural pre-cast concretes for industrial buildings and other civil engineering works. The successful implementation was monitored (technical and environmental performance) compared to standard pre-cast elaboration procedures, concluding that process costs remain unaffected [

48]. As for the demo case, ‘Green Liquor Dregs (GLDs) and slaker grits (SG) in bituminous mixtures’, the GLDs were employed as aggregates in bituminous mixtures of asphalt road pavements. Remarkable technical issues such as extra costs coming from their pretreatment based on salt removal, drying and sieving were overcome. Thus, waste mixtures achieved acceptable technical and environmental performance and good workability during road layer construction procedures have been proven to be successful, not increasing the process costs and giving a good technical and environmental long-term performance. Regulatory support and incentives (taxes, green purchases, etc.) in the EU can be very variable and can be a definite barrier to lime ash exploitation as it originated from a waste, despite its excellent performance.

4.2. CBM 2: Innovative Circular Business Model for Eco-Hydraulic Road Binders (HRB)

The CBM 2, located in Spain, focuses on the valorisation of waste paper fly ash (WPFA), a waste generated in the energy recovery of paper rejects coming from the paper recycling process. WPFA is intended to replace cement and lime as a hydraulic road binder (HRB) employed in soil stabilisation for road construction.

In the initiation phase the CBM ecosystem was initiated by the construction company that led the CBM set-up process by encouraging the Spanish PPI, with the support of the regional government and R&D institutions, aiming to achieve both companies’ sustainable goals through a reduction in the landfilled WPFA amount, reducing the uncertainties about resources use as well as decreasing costs and carbon footprint in construction. The readiness for a collaborative innovation process was high due to an existing industrial cluster by which partners knew each other in previous supply relations and due to a favourable site location. Regarding the strategic goals, the expected impacts for involved companies (market, social and environmental) were high: valuation of cheaper materials within a closed-looped system, reduction in waste disposal and higher economic growth. The CBM leader’s extensive experience in applying CE principles within the construction industry and successfully delivering innovative and competitive construction products and services benefit the collaboration.

Throughout the ideation phase, the valorisation technologies and processes for WPFA quality improvement, compositional variability monitoring, waste collection, storage, and delivery and its specific dosage method in HRB were defined in detail [

49]. The investments required were affordable for the implementation of the process and the main concerns pointed to the diversity and quality variation of some WPFA chemical compounds to work safely, guaranteeing no harm to human health and the environment through a proper dosage mixing and monitorisation plan, and the regulatory constraints on waste management and application in road infrastructure. The production and commercialisation of WPFA as a “by-product” face legal difficulties due to certain interpretations of the by-product definition itself. The lack of a WPFA regulatory status as a secondary raw material in construction related to use constraints, mechanical, environmental and durability performance of WPFA in HRB products and its economic feasibility were relevant roadblocks to overcome. In terms of the valorisation operation, a quality upgrade of the WPFA was required through the addition of some performance-enhancing additives, and demonstrating the social, economic, and environmental benefits to the respective legal authorities. However, the Spanish General Technical Specifications for Roads and Bridge Works (PG-3) applied to HRB did not mention WPFA and, therefore, the construction sector was reluctant to use them, constituting a significant obstacle. To overcome this issue, a technical conformity report (TC) was developed for WPFA use, with the collaboration of an R&D technological centre, by which a new product called CALCEM was described and evaluated by the requirements defined for the Spanish applicable regulation. It was envisioned that no special skill or high investment in innovative operation equipment was foreseen for product development and application. As far as the detailed economic and financial analysis is concerned, the geographical factor or maximum WPFA delivering feasible distance and the enterprise’s economic incentives or disincentives to engage in such environmentally sustainable development were identified as the most critical factors to be controlled in a later phase. During this phase, risks associated with waste management and environmental impacts, such as the presence of heavy metals and chlorides, were assessed. To prevent unacceptable impacts on soil, groundwater, surrounding vegetation, and human health during construction, an environmental monitoring plan for potential risks was established.

During the integration phase, the collaboration framework between the constructor as the CBM leader, the WPFA provider and three R&D organisations was established. Similar to the CBM described previously, each of them provides technical support in different activities. The network dynamic depended on the intermediating role of the CBM leader who, in collaboration with one R&D centre, developed the new WPFA-based HRB and outlined the pilot-scale demonstrators. Additionally, the LCA of the new solution and an environmental risk assessment were made by technological centres specialised in those analyses [

50]. Even though the technical and economic feasibility of this CBM was demonstrated, its deployment faced regulatory barriers, necessitating organisational and managerial changes at the waste manager and SRM producer levels. This posed challenges and caused delays in the establishment of the CBM, which have recently been overcome.

During the implementation phase, three demonstration pilots were carried out, corresponding with the three types of stabilised soil layers included in the Spanish road regulation. Overall, WPFA has a lower density than standard raw materials, implying increased transportation costs limiting the delivery distances for a feasible CBM. It was concluded that WPFA could replace cement and lime satisfactorily in stabilised-soil road layers, while environmental risks, mostly related to dust generation during in situ HRB mixing with soil, can be acceptable and properly managed [

51]. Quality control demonstrated the compliance of the new HRB with all technical and environmental requirements at affordable process costs; therefore, a technical conformity report (TC) was launched (in progress) for a new product called CALCEM.

4.3. CBM 2: Innovative Circular Business Model for Eco-Hydraulic Road Binders (HRB)

This CBM valorises a proper mix of PPI waste deinking paper ash (DPA) and deinking paper sludge (DPS) produced in Slovenia, as the result of the recycling treatment process of paper, to be used as a new composite material for infrastructure construction, serving as a light backfilling material for the consolidation of slopes. The new by-product, named MUDIPEL

® [

52], has served as a backfilling material to stabilise a slope located along a railway line in Slovenia, a mountainous country with landslides potentially threatening the safety of railways, which have been addressed through costly actions. CBM 3 was shown to reduce the material needs and costs of Slovenian railway renovations with the urgent need for sustainable renovation activities further than normal operation.

During the initiation phase, a group of industrial partners committed to solving the challenge and taking advantage of the opportunity of obtaining relevant PPI waste landfilling reduction worked together to exploit a unique solution for sustainable and cost-efficient renovation of railways in Slovenia. The CBM leader, in this case, was a Slovenian R&D centre that encouraged the DPA/DPS producer (PPI), the construction SME and the railway manager to create the new industrial ecosystem. The primary motivation for initiating this CBM was the unavailability of a suitable landfill in Slovenia for the waste type (DPA/DSP), which resulted in significant efforts being made towards recycling or incurring high expenses for landfilling in neighbouring countries. The readiness for collaboration was promoted by existing research experiences; participants worked together previously in research projects. In terms of systemic changes for the companies, the solutions were expected to impact the managerial and organisational dimensions and marginally modify some technologies. Some remarkable impacts were foreseen such as cost savings for the waste producer in terms of lowering landfilling, positive effects on the product sales (new markets), increased prestige and reputation, becoming a qualified supplier for sustainable products through the valuation of materials within a closed-looped system, considering approaches to build trust, risk taking, learning and training, sharing costs of research and branding/marketing. Aspects such as the Slovenian social framework, where the environmental concern of the public is the highest among all European countries, the lack of large-scale, long-term experiences, potentially higher costs than natural raw material, and transportation and operative issues were carefully explored in this phase. These activities demanded special effort regarding key activities such as communication (demo publications and conferences, newsletters, network events, marketing communication, social media), promotion of technical and legal discussions/legal lobby (Geotechnical, construction, paper Industry societies), marketing (advertising in the construction society), networking (new stakeholders in the circular case and Construction companies), and encouraging social awareness about CE (e.g., lectures in the Slovenian Chamber of the Commerce).

The ideation phase was oriented toward the eco-design and implementation of the new processes and demonstration activities. It implied efforts on recycled material homogenisation, transportation, construction standardisation (Slovene Technical Approval STS), scaling-up, established de-investment planning, logistical needs considering the product adaptation to the Slovenian climate conditions and establishing a testing plan for waste quality and product technical and environmental performance continuous monitoring. In addition to searching for the best mixture dosage, one of the main challenges was to obtain new skills in the effective mixing of components, so a new mixing equipment was ideated. This phase also addressed the constraints of there being no wastewater and that gases could be produced. When the economic viability analysis was carried out and compared to classic (‘linear’) solutions, mixing was identified as a potential major up-front investment cost. The assessment predicted that the valorisation process was potentially competitive concerning standard procedures including long-term environmental monitoring costs, despite no subsidies existing from local government. The absence of specific norms to use these waste mixtures in the targeted uses supposes obtaining legal approval before implementation is possible, which can be very different across the EU. The environmental risk and LCA analyses were established focusing on the leachate potential of certain compounds that may impact groundwater and soils [

50]. Additional activities to encourage the transition to CE were also planned, gaining target stakeholders’ (society, government) attention and acceptance, through intense communication and managing resistance in a very conservative construction sector. Finally, KPIs were settled involving not only technical and economic indicators but also financial social and environmental indicators.

The integration phase set up the collaboration framework between the R&D institute as the CBM leader and giving scientific and technical support to the industry, the PPI as the DPA/DSP provider, the construction SME and the railway manager. In this collaborative scheme, the R&D centre developed the DPA/DSP study in mixes and evaluated their environmental performance, the PPI provided the waste and information on their composition and qualities, and the infrastructure manager (railway) contributed to specification of the work scope and engineering requirements of the new infrastructure, whereas the constructor supplied its construction experience and was responsible for the execution of the infrastructure (gabions, retaining wall) with the new material (MUDIPEL®).

One demonstrator case was developed in a railway application in Slovenia during the implementation phase. A 50 m-long retaining wall was built and almost 100 Tons of the new composite MUDIPEL® was used as a back-fill material set behind the retaining wall. The new by-product was validated (with STS-Slovenian technical approval) before pilot-scale valorisation. Its elaboration required proper material handling and superior efforts than standard procedures on mixing homogenisation and compaction. It also required new skills and processes and adapted equipment, enabling constructors to build fewer gabions per length. Continuous control during the production, mixing and installation stages of MUDIPEL® was crucial. Despite the increased technical complexity, the new by-product elaboration is affordable for the sector as long as industrial equipment can be easily adapted to the new process. Although it showed optimal technical and environmental performance, the lack of specific EU regulations and standards about DPA/DPS use as back-fill material impedes widespread faster market penetration.

4.4. Cross-Comparison

Some reflections on the key success factors for the replicability of the three CBMs were explored (

Table 3) since the replicability landscape can be used to understand to what degree the valorised wastes and their associated processes could be successfully developed and commercially exploited when the CBM is created with different stakeholders, or under different geographical conditions, or even considering different applications.

Applying the conceptual model shown in

Figure 1 to three circular case studies, the authors were able to collect significant empirical data and the analysis was deployed at the level of the business innovation ecosystem, that is, at the level of actors and organisations and their collaboration in the whole industrial symbiosis scenario. Its main building blocks (circular vision, materials reuse scheme, CE collaboration scheme and adequacy and benefits) were integrated into a phase-based approach to align the management steps of a CBM design with an innovative viewpoint, starting from identifying the value proposition, progressing through the creation of the business ecosystem model, and culminating in a coordinated CBM.

The requirements for a new methodological framework derived from the literature review and the first iteration round (interviews) with the participants in the three case studies were explored. These elements were as follows: to identify the role of technological and non-technological aspects within the CBM, to incorporate the perspective of the ecosystem and its value proposition and all activities and processes to guarantee not only economic but also social and environmental impact in the CBM whole lifecycle, and, finally, to provide guidelines for the different phases of CBM life cycle. During the validation sessions in the second iteration cycle (creative workshops), the framework requirements and its initial format were critically discussed and valuable suggestions for improvement were received including an additional explanation of some of the main management tasks of the CBM to provide examples of objectives and strategies or KPIs most commonly used in CE and to provide a useful checklist of the main recommendations before setting up the CBM.

The approach allowed the extensive exploration of the CBM process and the collection of relevant insights concerning the encountered barriers and enablers. In particular, technical and non-technical elements were explored in detail including aspects such as leadership, governance, organisational readiness or patterns. Then, the opinions, experiences and recommendations from stakeholders involved in the CBM were captured to understand the effect of a comprehensive list of factors that can endorse or constrain the practical implementation of the CBM. As a result, integral management guidance to those organisations that operate in the field of circular economy and aspire to gain competitive advantage was deployed.

It is important to note that its components were specifically developed for the pulp and paper industry (PPI) and one of the demand sectors, namely construction. These sectors actively participated in the design of such a methodology, providing significant feedback. The action research approach, proposed in the three case studies, was implemented in a four-year project (‘paperChain’ EU-funded project, GA nº: 730305) during which researchers observed and reflected upon the process of creating circular business models.

5. Discussion

As many scholars have highlighted, further empirical studies and business cases are required to indicate a way and guide organisations in fulfilling the transition towards circularity [

6,

42,

53]. In this study, we sought to bridge the gap between theory and practice by illustrating the relevant factors emerging throughout the four phases of the methodological framework (built to overcome weaknesses and missing aspects of previous developments in the field of CBM). We contribute to the spread of literature on circular business models, waste valorisation and resource recovery strategies. Circular business models like waste valorisation achieve the optimal solution by establishing connections with various sectors or industry branches, and technology must be capable of bridging the inherent gap between diverse industry sectors [

42], and within the concrete operations that support the implementation of CBMs explored by Hofman (2019), collaborating within value creation business networks is frequently highlighted for the development and successful implementation of CBMs [

47]. Moreover, the potential benefits that a strengthened business network including dynamic SMEs (focused on niche products) and large-scale multinationals (focused on bulky products and economies of scale of pulp and energy) would provide to PPI [

20]. In this regard, this research provides practical examples of successful collaboration between different industrial sectors that are moving forward to circularity in which trust within the ecosystem’s business actors is even more relevant than the technological aspects. These case studies have shown that managers demand additional explanations concerning all management, control and monitoring tasks of the CBM design and operational execution as well as examples of the strategic objectives and KPIs that are most commonly used in CE. In this regard, the role of the CBM leader in connecting various stakeholders seems especially crucial in the overall success of the CBM. It will not only manage the definition of the CBM model’s strategy from an ecosystem perspective after elucidating the motivational factors of participation in a CBM but will also explore the involvement of strategic partners from their added value provided according to the transition model scheme. The overall success of the CBM will depend on its ability to actively engage the stakeholders within the whole lifecycle of the methodological phases. New types of collaboration can emerge and be explored to stimulate innovation and ensure that involved parties create value for the supply chain in the CBM. This requires leadership from an ecosystem view (organisational support through new collaboration processes of co-creation between stakeholders, clients and supply chain partners). Additionally, personal connections are key to defining the established vision and ambition of the project and, consequently, the success of the CBM.

Nevertheless, the application of the methodological framework in real-world scenarios has uncovered significant and specific barriers that need to be addressed in future developments or by regulatory bodies at both the European and national levels. From a technological dimension perspective, the framework implementation allows companies of the CBM to notice the need for skilled workers in CBMs, the lack of efficient new recycling equipment and processes, and the need for the establishment of quality control/quality assurance (QC/QA), and CO2 footprint assessment leads to disadvantages for CBMs, enabling a complete view of each CBM to be attained. The economic perspective creates more limitations that hinder the CE transition such as the absence of green labelling for secondary materials at the EU level, landfilling remaining too affordable in many countries and regions, the lack of material availability and dependence on distance, the low awareness of the economic interest of adopting a circular model, natural raw material costs/pricing still being very competitive, and green procurement/opportunities from the public sector not yet being consolidated and well understood. Moreover, social limitations were discovered with relevant impacts on the CBM such as low public awareness of the circular economy and low trust in “waste”. Finally, from the regulatory landscape, relevant limitations were discovered through the CBMs shown in this article related to the existence of very different waste implementation plans across EU countries and regions, unequal “end of waste” (EoW) and by-product declassification procedures at the national and regional levels, and the green public procurement implementation rate being unequal among EU members.

6. Conclusions

By leveraging findings from three case studies with a resource recovery strategy conducted in Portugal, Spain, and Slovenia, the authors shape a phase-based implementation guide for waste valorisation strategies intending to enhance the circular economy (CE) transition within a cross-sectorial collaboration scheme between the pulp and paper industry (PPI), construction sector and public institutions.

Factors that influence the

initiation phase of the analysis may emerge, primarily with a strategic nature tied to the creation of the CBM’s value proposition as a business ecosystem. The strategic vision of members plays a crucial role in recognising the CBM opportunity, promoting its ideation [

5,

43] and identifying their added value to the CBM ecosystem [

35,

47]. The leadership role in the CBM is also important but can change over time for increased effectiveness as supported by the empirical evidence.

Significant factors arise during the

ideation phase, where technological, economic, legal, and environmental challenges are recognised and need to be addressed by circular solutions [

21,

35,

44]. Upon evaluating the technology dimension, it becomes evident that new technological advancements may not necessarily lead to radical innovation, and the industrial scalability of incremental innovations will be crucial in this sense. Case studies have revealed that the economic viability can be highly influenced by significant challenges for technology providers such as transportation conditions and its legal aspects. Various processes are economically essential, including analysing the viability of the new solution compared to traditional linear options and assessing the economic feasibility of large-scale industrial production. Factors such as finance mechanisms supporting a circular economy approach (e.g., new taxes or reduced taxes to natural material use vs. labour material) as well as the regional or national public incentives to boost either the valorisation of wastes or the production of SRMs have been mentioned in the three cases. The legal dimension will be enhanced as the project progresses, addressing existing barriers and pushing to establish new policies. The social dimension plays a crucial role in the success of CBMs since CBMs are not well understood or recognised by society due to, for instance, a lack of eco-labels and information about their true impact. To foster social awareness of the circular economy’s significance, companies involved in CBMs should implement a robust communication strategy targeting (1) society and end users, (2) internal communication, and (3) sector-specific communication.

To ensure the long-term sustainability of the CBM, it is essential to regulate and formalise the collaboration scheme during the

integration phase. Three cases coincide in agreements among partners that rely on informal or verbal contracts and trust, lacking a suitable governance model for the ecosystem. However, they also show that by establishing formal governance rules and policies as well as clear roles and obligations, the ecosystem’s members can enhance their dialogue with national or local governments and overcome institutional obstacles, thus strengthening the CBM [

6,

35,

40].

The

implementation and evaluation phase has highlighted the interconnections between the CBM and the organisational readiness of participating companies. This phase in the three cases shows the necessity of the creation of various processes, new skills as a key to design for a sustainable future, activities within each company, and overcoming undetected issues in the previous phases [

54]. Empirical evidence illustrated that new strategic goals and cultural values around CE and CBM become integrated into the company’s idiosyncrasy. Moreover, in this phase, all members of the ecosystem should designate a key responsible person such as a circularity expert, who ensures that the vision of the model is maintained throughout its lifecycle and keeps team members informed and motivated. Regarding the dynamic evaluation and monitoring set of the CBM, partners’ responses have indicated a shared understanding of its significance. They emphasised the need to incorporate key aspects as the project advances, such as balancing fixed targets with a dynamic plan to overcome barriers.

The three cases presented in this paper serve as practical illustrations of the tested methodological framework for CBM, showcasing best-practice business case examples and lessons learnt as well as other published circular initiatives and experiences [

55,

56]. Overall, the methodological guide demonstrates significant flexibility for application in various industries, provided that a comprehensive analysis of all relevant variables is conducted. In this context, it is important to emphasise that the methodological framework can be readily customised to suit the unique characteristics of alternative circular economy strategies, such as product life extension. However, it is essential to acknowledge that while this adaptability exists, new challenges and corresponding solutions may emerge in the process. Similarly, the methodological guide endows managers with a holistic framework encompassing the various dimensions impacted by the development of new products or services. This framework empowers them to effectively address emerging constraints. The integration stage, in particular, is expected to offer solutions to these challenges, which may involve actions like negotiating agreements or providing technical compliance documents, as discussed in the paper.

Nevertheless, additional advancements and improvements can be accomplished by subjecting the method and its guidelines to testing in diverse sector-specific contexts, alongside different circular economy strategies and geographical regions. This approach would facilitate the identification of disparities in participants’ perceptions of barriers as well as foster a deeper comprehension of variations in corporate culture. Furthermore, additional areas for enhancing the implementation of the guideline include the application of digitalisation to support managers during that process. In this sense, considering the role of ICT in triggering and enabling the adoption of CBMs, the development of a decision support system (DSS), which can be built upon existing or novel repositories of strategies, objectives, roles, and actions (derived from existing literature on CBMs), will complement the initiation and ideation phases helping to select the key circular business model considerations. Digitalisation would also contribute to potentiating the joint benefits of applying the “transition model” and the “monitoring framework” within the CBM. The implementation of an efficient monitoring system for critical KPIs would help extend the benefits of CBM within the members of the ecosystem and further replicability, thereby contributing to expediting the desired transition to a circular economy. Given the relevance of the transition model to be created in the initiation phase, which models the economic feasibility of the CBMs over the traditional linear models (covering the cost structure and the revenue streams), a digital tool for modelling all the activities, costs and benefits involved in the CBM would help to better communicate the stakeholders the economic and technical viability of the CBM.

In addition to the regulatory barriers discovered in this research, this paper underlines the need for urgent future investigations into policies that impede the circular economy transition whilst offering new possibilities to reform and enhancing existing frameworks.

Another significant area for progress pertains to the exploration of implementing multiple CBMs at both the national and EU levels, as this would significantly expand the benefits of circularity. Active sectoral collaboration with the business sector is essential for effectively elucidating novel opportunities for novel CMBs. More concretely, looking at future directions in the field of waste valorisation strategies, some areas to be further explored are demolition wastes from the construction sector or fish waste recovery. The PPI would encounter new business pathways in virtue of valorising lime mud, dregs and grits to other applications in agriculture and environmental technology, alternative applications of valorised WPFA as a filler for asphalt mixtures and partial substitution of cement, and mineral addition for concrete elaboration.

Derived from the empirical evidence of the three cases, their replicability potential was explored. As a result, the following specific recommendations are proposed for practitioners to ensure not only the success of CBM but also its potential for replication in different contexts and geographical applications:

To involve experts with high-level knowledge of supply chain management and the diversity and quality of wastes to promote sectoral replication (influence the properties of the new product);

To evaluate requirements of new recycling equipment, processes and quality control procedures across other countries;

To be aware of the negotiation efforts needed to achieve beneficial waste supply conditions as well as logistics;

To be involved in networks, industrial clusters or associations to promote joint efforts for a better CE transition;

To set up an innovation team featuring staff with innovation and holistic view profiles, risk takers, and external partners and ensure circular economy awareness among the members of the innovation team.